Acoustic Treatment and Soundproofing

We provide services for planning, design and implementation of most Acoustic Treatment and Soundproofing applications. Our trained installation personnel will guarantee you get the maximum benefit out of any installed assembly according to your needs. Contact us for a free visit to your site where we will make recommendations according to your requirements, a presentation of available materials to work with, and suggest possible solutions using computer 3D models.

What is the difference between Acoustic Treatment and Soundproofing?

ACOUSTIC TREATMENT

Acoustic Treatment addresses the quality, intelligibility and level of sound INSIDE a room and has nothing to do with how much internal sound is or is not heard outside the given room, or how much external sound is leaking from the outside into the room.

Reflective surfaces within a given finished room cause sound impacting these surfaces to be reflected and bounce around within. This gives rise to a number issues which can be the cause of problems.

1 – Reverberation

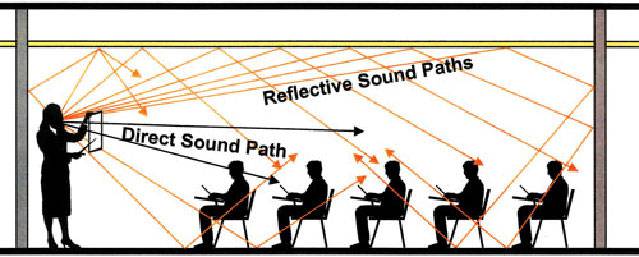

Inside a given internally reflective enclosure, the human ear receives:

a) Sound directly from the source in a straight line.

b) An undefined number of “copies” of that sound which have bounced off the reflective walls, ceiling and floor before reaching the ear

2 – Sound Quality

One of the properties of reflective materials is the reflection of different frequencies of sound at different intensities. The resultant sound therefore exhibits a change in equalisation as compared to the original. This is not so much of a problem in a speech-oriented enviroment, but is completely deterimental to music listening enviroments such a theatres and studios. |

3 – Sound Level

The addition of reflected sound to direct sound causes the general sound level within a given room to increase. In an enclosed enviroment, this can be annoying and can cause un-percievable stress as well as issues with communication.

Typical problematic scenarios

- Meeting/presentation in a boardroom or conference room where the listeners are not clearly understanding what is being said.

- Attending a performance in a theatre and having a bad musical experience because the sound is not right.

- Sitting across a table in a restaurant and having to lean forward and talk louder to make yourself understood.

- Inability to properly concentrate in an office enviroment because everybody can hear what everybody else is saying or doing.

- Machines in a wokshop or factory enviroment causing added sonic stress to the operators, every day of the week.

REFLECTIVE MATERIALS

- Ceramics

- Marble & Granite

- Stone / Concrete Walls

- Gypsym / Plastic Surfaces

- Metal

- Glass

ACOUSTIC MATERIALS

- Acoustic (porous) Gypsum

- Wood

- Fabric

- Polyster Fiber

- Rubber Compounds

- Mineral Fiber

- Polyurethane

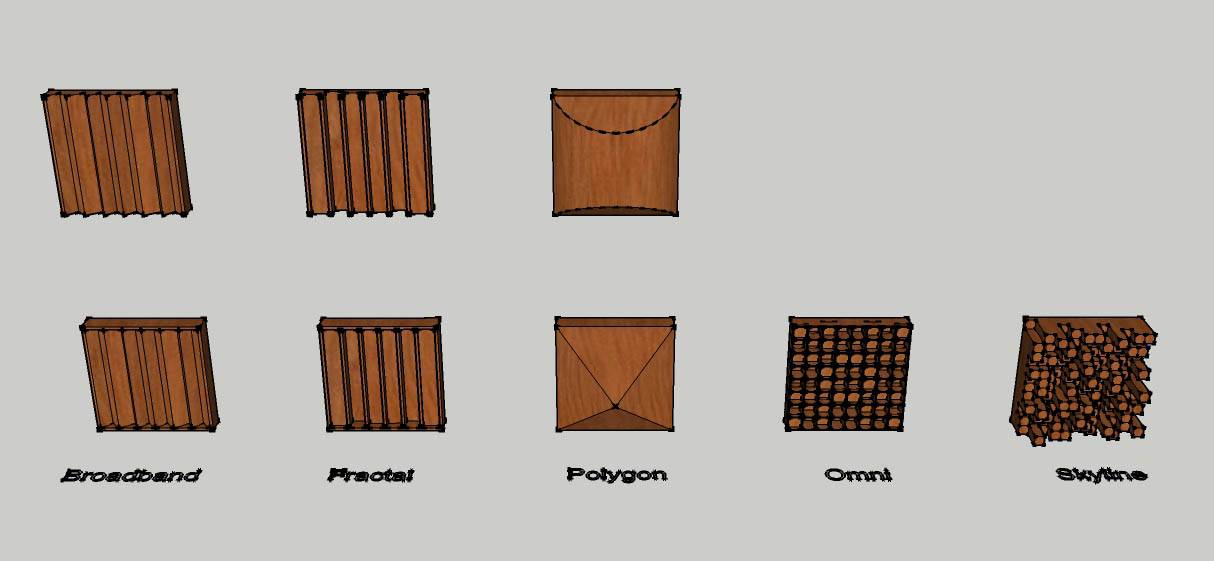

Treatment

Acoustic treatment involves the use of non-reflecting and/or diffusing sufaces in order to reduce reflected sound to acceptable levels according to the particular function of the room or enclosure in question. Absorbers and diffusors are available in various models, materials, shapes and sizes to suit all applications.

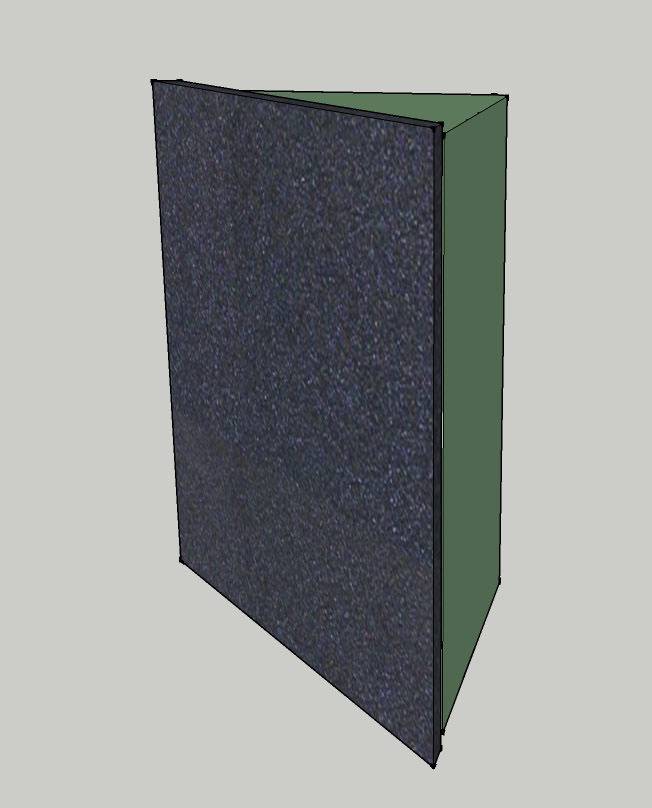

Absorbers absorb most of the sound incident on them, therefore eliminating all reflections.

Diffusors scatter sound in all directions, creating ambience and eliminating directly focused reflections.

Depending on the particular application, utilisation of absorbers, diffusors or both may be required as necessary.

In professional enviroments, where the required specification is more rigorous, internal surfaces are almost entirely composed of acoustically performing materials.

In commercial or executive enviroments, solutions are attained by using an acceptable amount of absorbant surfaces to balance out the effect of reflective surfaces. There are endless possibilities in this respect. This may mean, for example, installing a sound-absorbant ceiling to balance out the effect of a reflective wall and a reflective floor, treating part of a surrounding wall, treating a floor and/or acoustically treating fitted (un-movable) internal installations and furhishings, depending on the required use of, and finish required in the particular enclosure. In any case, the general idea is to avoid creating a finished room or enclosure composed entirely or almost entirely of reflective surfaces.

The large selection of un-obtrusive materials, direct replacement materials and even designer materials available for implmentation of acoustic treatment nowadays guarantee a finish which is in total conformity to the design and style required – No, it does not have to look like a recording studio at all

Soundproofing

Contrary to popular beleif – soundproofing addresses the amount of sound entering or escaping a given room, it does NOT address the quality, intelligibility or necessarily the level of sound within the room.

Soundproofing is as strong as the weakest link in the chain. Therefore the performance of a 64db soundproof wall which has a 25dB door installed within it will be 25dB.

In situations where both soundproofing and acoustic treatment is required, soundproofing is implemented first, followed by acoustic treatment.

Types of Noise

Airborne noise is sound travelling through air. It can be blocked by installing an adequate sound barrier between the offending sound source and the area requiring protection.

Typical airborne noise includes vehicle noise, car horns, human noise (shouting, laughing, singing etc..) sound from TV sets and other loudspeakers, sound made by office and domestic machinery and small electric motors, fireworks, gun-shots and aircraft fly-by. The louder the noise, the higher the specification of the sound barrier must be in order to blank that noise out completely.

Impact noise is the transmission of vibration caused by an offending object impacting or directly vibrating another surface. The vibrations travel through a connecting solid and up or down walls and ceilings until they reach your domain, where they can be heard.

Impact noise also generates sound in air (airborne noise) because the vibrating surfaces in contact with air cause the air to vibrate in sympathy and transmit sound. This is how the sound is heard on the assumption that one’s ears are not in physical contact with the vibrating surface(s), apart from the possibility of actually feeling the vibrations should the impact noise be extensive.

Impact noise is ideally addressed by architecturally designing a building which stops the transmission of vibrations. If the building shell is not designed accordingly, it is almost impossible to eliminate this kind of noise completely, though varying improvements can be made depending on the gravity of the situation.

Typical impact noise includes nearby passage of heavy vehicles (large trucks, trailers, trains etc..) , jumping or walking on a floor with heels, moving of heavy furniture, use of hand tools impacting a surface (hammers, drills etc..), percussive instruments (bass drums, toms etc..), nearby construction machinery (jack-hammers, jiggers etc..) service units (generators, chillers, power transformers, etc..) and other heavy industrial machinery installed directly to a surface with improper shock absorbtion (pump systems, etc..).

Very loud, low frequency soundwaves (bass) can also cause floors and walls to vibrate, causing audible impact noise.

Common causes of Inadequate noise-control

Windows

Poorly fitted windows and windows unable to provide an air-tight seal on closure are subject to air leakage and are therefore poor soundproofing peformers. Also, lack of proper double glazing using the proper glass considerations, improper gaps between glazing, and poor materials used to manufacture the window frame all cause considerable degradation to soundproofing specifications.

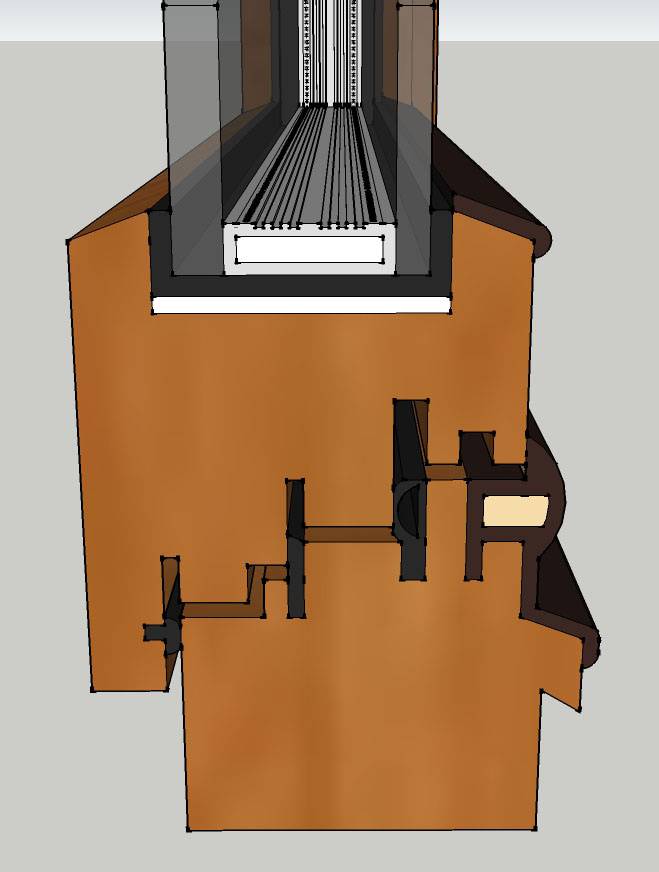

Soundproof window 47dB, triple seal, 20 Argon

Soundproof door single leaf and full lock frame

Doors

Doors which are unable to provide a proper seal (that includes the gap between the bottom of the door and the floor), and which do not contain the required mass to stop soundwaves travelling right through them are poor soundproofing performers, irrelative of the material used within the door shell..

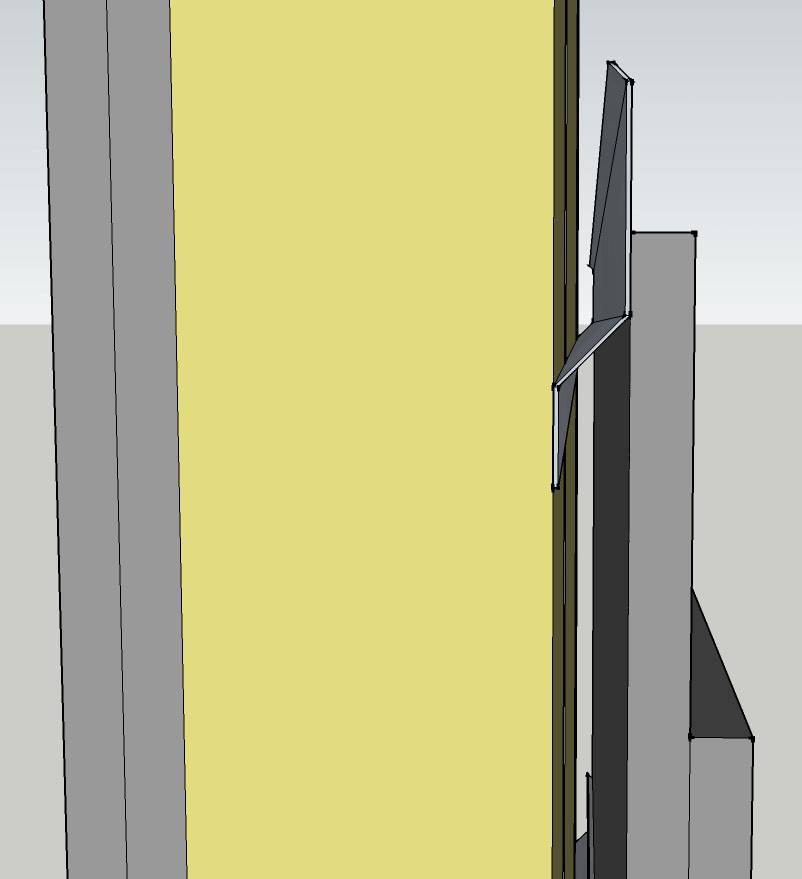

Partitions

Partitions using materials which are inadequate on their own, single gypsum layers, or the wrong type of framework for the specific job are poor soundproofing performers. The workmanship (as far as special considerations in view of soundproofing during actual construction of the partition) is also responsible for up to 50% of the final result, irrelevant of the materials used.

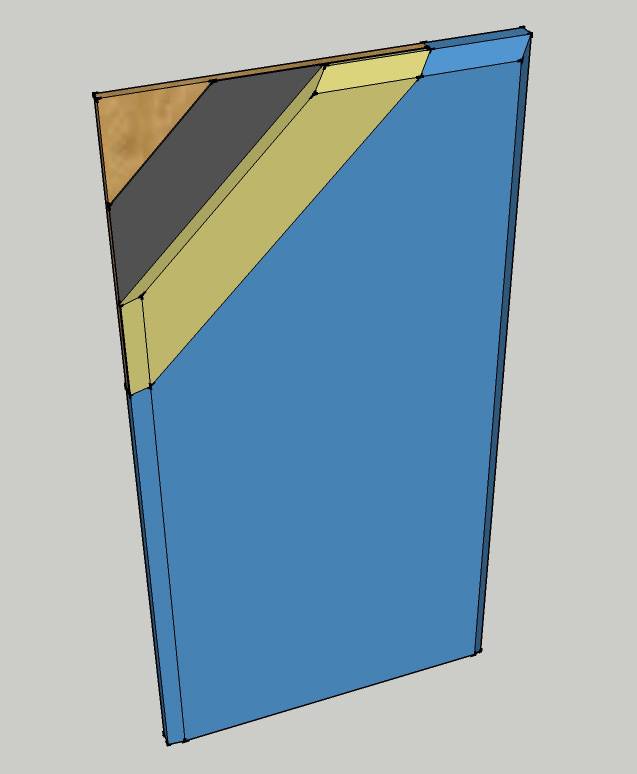

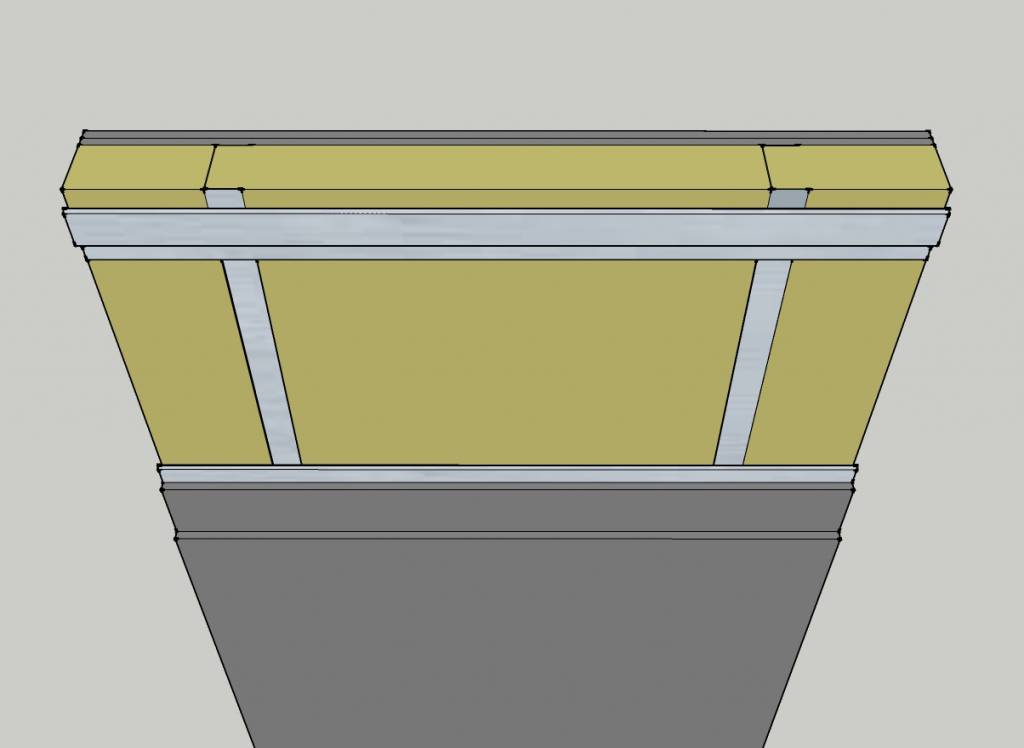

Example of spring-mounted panels in soundproof partition, where the frame is attached to the floor and ceiling via shock absorbers (not visible)

Mineral fibre cladding (sometimes universally referred to as Rockwool) is a great performer in acoustic treatment applications, but it lacks substantial mass, and therefore is not a great soundproofing performer working on its own. It must work alongside other key-player materials such as shock absorbers and spring mounts. Choice of the right type of cladding is also a key issue in view of the increasing variation of specifications exhibited by similar products, some of which are more tuned to address thermal performance rather than sound absorbtion.

Inadequately constructed walls also exhibit a relatively much poorer soundproofing performance than expected. The amount of sound attenuation provided by a wall varies immensely according to factors below:

- What is the wall made of? Concrete bricks, stone blocks or a combination of both?

- Is it a single or a double wall?

- What is the width of the concrete brick or stone block used in this wall?

- What is the type of stone used, or the grade of concrete or aggregate used to constitute the brick?

- If it’s a double wall, then what is the width of the air-gap between the two walls?

- If it’s a double wall, has the gap between walls been left clean or has any excess material been spilt into the gap?

- If it’s a double wall, are there any connecting cross-over bricks or stone blocks between the two walls or are the two walls un-connected and completely independent of eachother?

- How large or small are the hollow sections within the concrete bricks and what is their layout?

- Are the hollow sections within the concrete bricks filled in or left empty?

- If the brick hollow sections are filled in, what is the material used for filling and how densely has it been packed?

- Have the seams between all adjacent bricks been carefully grouted with the correct material BEFORE final plastering of the wall, or has the final plastering been applied over existing seams between bricks?

- Within what frequency bandwidth is the primary sound attenuation required?

Many websites tend to quote c45dB for a single concrete brick wall and c55dB for a double wall. These values are however unsubstantiated as they take too many factors for granted. It is also worth noting that most of the available tests producing such results are carried out with brick widths which are much larger than the ones available locally.

In reality, the sound attenuation of a “concrete brick wall” can vary between 36dB and 60dB, depending on all of the above variables. 60dB is roughly 16 times more sound attenuation as compared to 36dB.

All these factors will determine whether and what kind of additional soundproofing framework is required to be added to an existing wall structure depending on the specification to be attained, this being defined by the specific use of the room and the maximum noise levels within it.

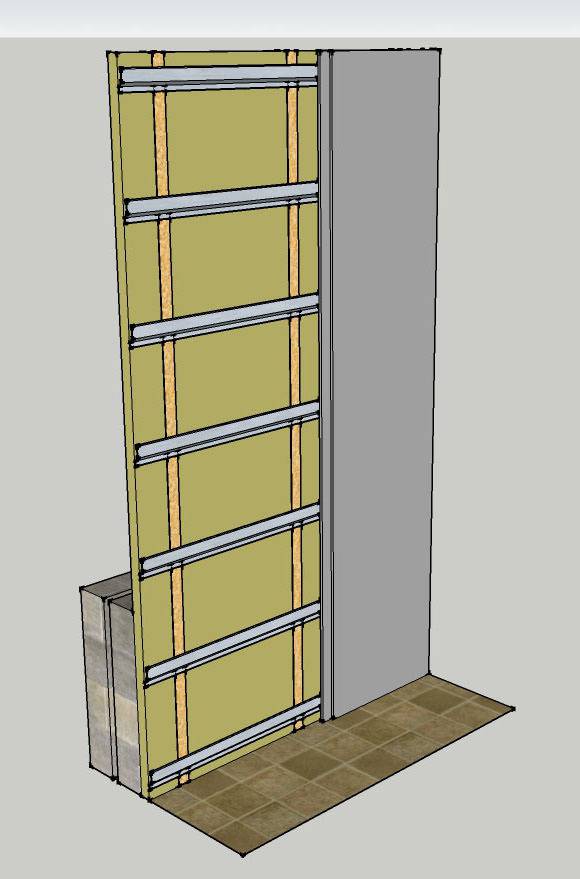

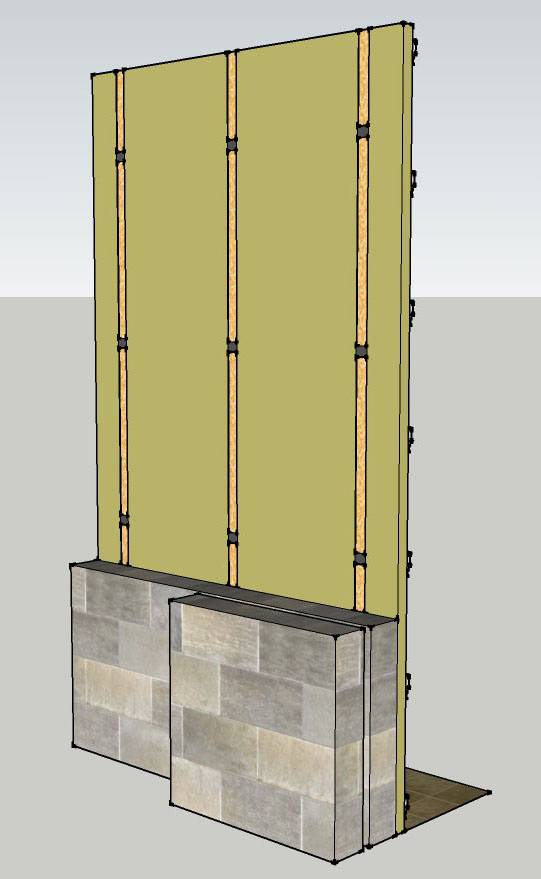

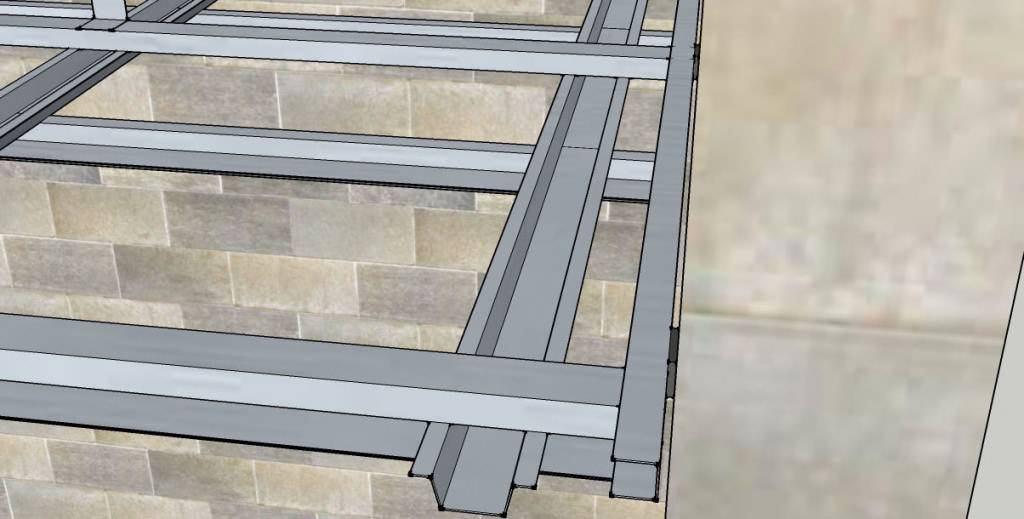

Wall soundproofing with main supporting wooden frame mounted on neoprene shock absorbers and spring-mounted double surface panels

Floors

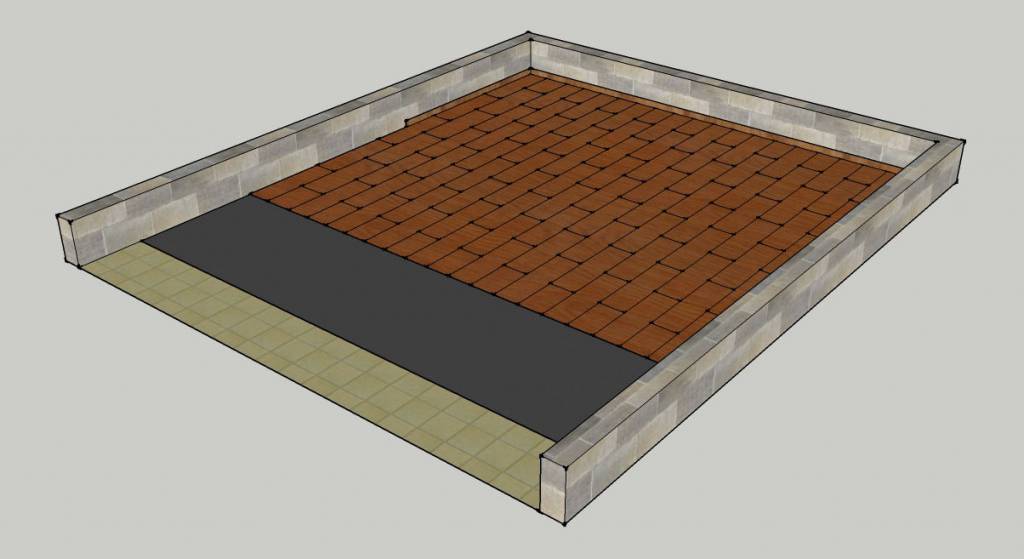

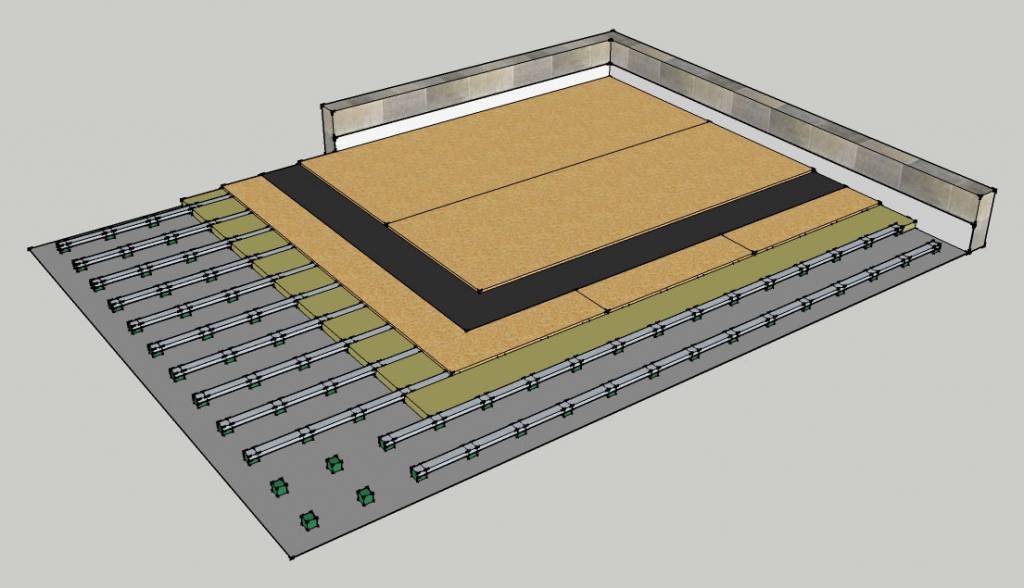

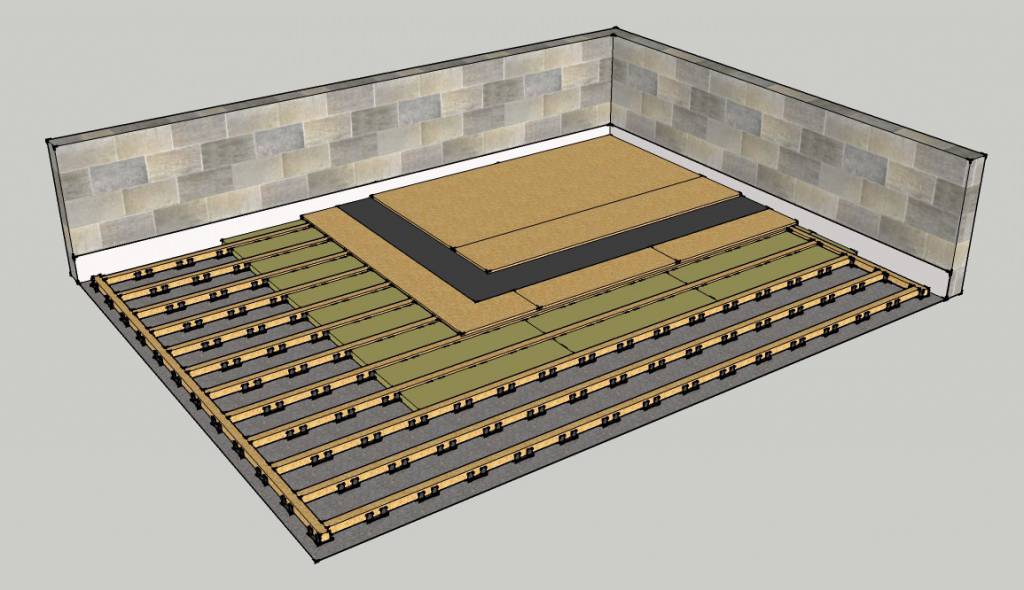

Un-treated floors are often susceptible to impact noise especially if they are above the ground-floor or basement. In most cases this issue can be treated acceptably, though one must keep in mind that nothing beats a floor in a well pre-designed building. There are essentially two types of floor treatments available, depending on the amount of absorbtion required:

A) Sound absorbant floors

B) Suspended (floating) floors – high impact

C) Suspended (floating) floors – low impact

Ceilings

Ceilings are commonly candidates for acoustic treatment, however in cases where loud sound dominates the room, soundproofing will be required. Soundproof ceilings also help to fend off impact noise originating from floors above.

Interaction of soundproofing assemblies

The way individual soundproofing assemblies (floors, walls and ceilings) interact with eachother at points of intersection or joining make a big difference to the final result, and this is highly dependent on the workmanship of the installer

What you need to know:

Soundproofing can be improved in two ways:

1) Adding sheer mass (dense material) to the existing structure.. eg: – building another wall (in the correct way) in front of the first with a suitably calculated air-gap which can (in the best case scenario) never be smaller than 50mm. This is not always possible on floors other than a ground floor due to architectural issues and also demands availability of appreciable (lost) space as regards length and width of the room.

2) Assembly of a shock-mounted soundproofing structure where the frame is not in contact with the wall, floor or ceiling, and allowing the outer spring-loaded visible surface to vibrate and absorb the sound by converting audible energy into kinetic energy (motion) and heat.

In certain cases both of the above treatments may be recommended. In other cases where only one of the treatments is required, the second option is a lot more space saving than the first.

There is no such thing as a standard soundproof barrier. The sound reduction rating of a given barrier needs to be 6db in excess of the offending noise source to be blocked. Therefore if the average sound level in a room is 55db, then a 61db partition will be required to block the noise to an adjacent corridor. It is quite normal to have partitions of different ratings in the same building, according to the particular room layout of that building.

Soundproof barriers must provide a full hermatic seal between the noise source and protected area. If there is as much as a crack or a pinhole anywhere, they will not work.

Mounting of an x dB soundproofing structure to an existing y dB wall, ceiling or floor, does NOT achieve x + y dB, but a lot less, reason being that the trapped air in the (relatively small) gap between one structure and another tends to compress and transmit some of the sound. In order to be able to happily add the separate ratings to produce a result of x + y, you need to have at least one metre spacing between the two structures. In all but a few cases this is not practical.

The performance of a soundproofing structure deteriorates as audio frequency gets lower. That’s why when you walk outside by a poorly treated night-club, all you can hear is bass.

Installation of soundproofing is a very delicate issue. Meticulous workmanship, good training and knowledge of how individual soundproofing materials are assembled into the required structure are critical to the final result. It’s not about getting it done, but all about how it’s done, and goes all the way from what is in contact with what, correct spacings between adjacent materials and spring mounts according to the particular application, right down to which screw lengths are used, where to use them and what they should and should not hold together.